NEWSContact us

Tel :

+86-750-3727377

Fax : 86-750-3727477 |

NEWSFive dimming methods to give you a comprehensive understanding of LED lighting!

Category: Industry information

Date: 2018-05-09

Click: 613

Collection:

Original Link: https://mp.weixin.qq.com/s/hKqqlnxp-OVPoK-CREI4BA

Rear edge Tangential (RPC) MOS tube dimming 3. DALI (Digital Addressable Lighting Interface) 5. The 0-10V dimming controller was commonly used for dimming control of fluorescent lamps before.

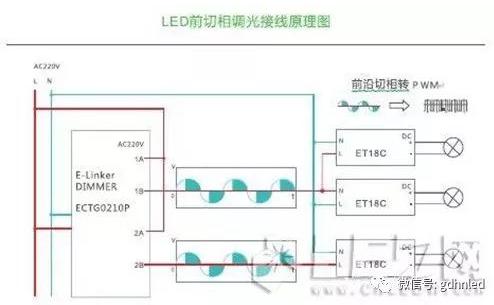

The principle of LED luminescence is different from that of traditional lighting, which relies on P-N junction luminescence. The LED light source with the same power, because of its different chip, current and voltage parameters are different, its internal wiring structure and circuit distribution are different, leading to different manufacturers of light sources on the dimming driver requirements are also different. LED luminous principle is different from the traditional lighting, is by P-N junction luminous, the same power LED light source, because of the chip is different, the current and voltage parameters are different, so its internal wiring structure and circuit distribution is different, resulting in the manufacturers of the light source on the dimming driver requirements are not the same. Therefore, the mismatch between the control system and the light source has become a common problem in the industry. At the same time, the diversification of LED also poses higher challenges to the control system. If the control system and lighting equipment do not match, it may cause the light to go out or flicker, and may cause damage to the LED driver circuit and light source. There are five types of LED lighting control on the market: 1. Frontier Phase Cutting (FPC), thyristor dimming 2. Rear edge Tangential (RPC) MOS tube dimming 3. 1-10V Dimming 4. DALI (Digital Addressable Lighting Interface) 5. DMX512 (or DMX) dimming Frontier Phase Cutting (FPC) dimming Front dimming is the use of thyristor circuit, AC phase 0 starting, input voltage chopper, until the thyristor conduction, there is voltage input. The principle is to adjust the conduction angle of each half wave of alternating current to change the sinusoidal waveform, so as to change the effective value of alternating current, so as to achieve the purpose of dimming. Frontier dimmer has the advantages of high adjustment precision, high efficiency, small size, light weight, easy remote control, etc., dominates the market, most manufacturers' products are this type of dimmer. Frontier phase control dimmer generally uses thyristor as a switching device, so it is also called TRIAC dimmer. The advantages of using FPC dimmers on LED lights are: low dimming cost, compatibility with existing lines, and no rewiring of the back edge tangent control dimming. The disadvantage is that the FPC dimming performance is poor, usually leading to a reduced dimming range, and will lead to the minimum required load is more than a single or a small number of LED lights rated power. Due to the properties of thyristor semi-controlled switch, only the function of opening the current, but can not completely turn off the current, even if adjusted to the lowest still have weak current flow, and LED microcurrent luminescence characteristics, so that a large number of thyristor dimming LED still have weak luminescence phenomenon after switching off, which has become a problem in the promotion of this wiring free LED dimming method

Rear edge Tangential (RPC) dimming The back edge phase control dimmer is made of field effect transistor (FET) or insulated gate bipolar transistor (IGBT) device. Back edge tangential dimmer generally uses MOSFET as a switching device, so it is also called MOSFET dimmer, commonly known as "MOS tube". MOSFET is a fully controlled switch, which can be controlled either on or off, so there is no phenomenon that the thyristor dimmer can not be completely off. The other MOSFET dimming circuit is more suitable for capacitive load dimming than thyristor, but because of the high cost and dimming circuit is relatively complex, not easy to do stability and other characteristics, so that the MOS tube dimming way has not been developed, thyristor dimmer still occupies the vast majority of the dimming system market. Compared with the front cutting phase dimmer, the back edge cutting phase dimmer applied in LED lighting equipment, because there is no minimum load requirements, so that can achieve better performance in a single lighting equipment or very small load, but because the MOS tube is rarely used in dimming system, generally only made of single lamp dimmer knob switch, this low-power post-tangential dimmer is not suitable for engineering applications. And many lighting manufacturers use this dimmer to adjust their own optical drive and lamps to do dimming test. And then their dimming products to the engineering market, resulting in engineering often with thyristor dimming system modulation after tangential modulation drive situation. This mismatch in dimming mode leads to dimming flickering, which can quickly damage the power supply or dimmer.

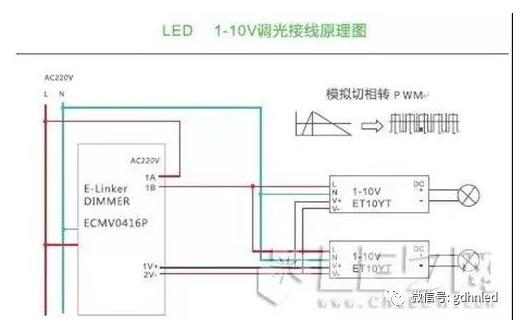

1-10V dimming There are two separate circuits in the 1-10V dimming device, one is a common voltage circuit, which is used to switch on or off the power supply to the lighting device, and the other is a low voltage circuit, which provides a reference voltage and tells the dimming level of the lighting device. The 0-10V dimming controller was commonly used for dimming control of fluorescent lamps before. Now, because of the constant power supply on the LED driver module, and there is a special control line, so 0-10V dimmer can also support a large number of LED lights. But the disadvantages of the application are also very obvious, low voltage control signal needs to add an extra set of lines, which greatly improves the requirements of construction.

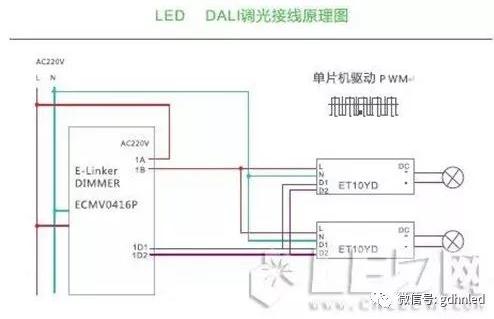

DALI dimming The DALI standard has defined a DALI network, consisting of a maximum of 64 units (addressable independently), 16 groups, and 16 scenarios. The different lighting units on the DALI bus can be grouped flexibly to realize the control and management of different scenes. In practice, a typical DALI controller controls as many as 40 to 50 lights, can be divided into 16 groups, and is capable of processing several actions in parallel. In a DALI network, 30 to 40 control instructions can be processed per second. This means that the controller needs to manage 2 dimming instructions per second for each lighting group. DALI is not a true point-to-point network; it controls ballasts instead of 1-10V voltage interfaces. Compared to traditional 1-10V dimming, DALI's advantage is that each node has a unique address code, and with feedback, the dimming will not degrade as 1-10V dimming does for longer distances, but in engineering practice, this distance should not exceed 200 meters. Obviously DALI is not suitable for LED lighting control. A DALI network can only control 21 full-color LED lights. DALI is oriented towards traditional lighting control, focusing on static control, reliability, stability, and compatibility of the system. The scale of LED lighting system is much larger than DALI system, which mainly pursues the artistic effect and expressive force of lamps and lanterns, and properly considers the intellectualization of the system, which requires the system to be connected to a larger bus network, with unlimited expansion ability and high scene refresh ability. As a result, the DALI system is often incorporated into other bus systems as a subsystem in large lighting projects. While the advantages of DALI dimming are not much to go over, the disadvantages remain the unnerving signal line layout and high price tag. It is worth mentioning that in order to ensure that the MCU is always in standby state, the current DALI is still required to standby power consumption when the lights are turned off.

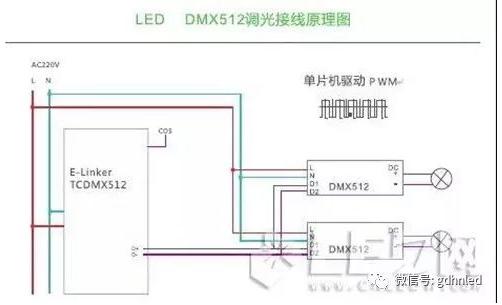

DMX512 dimming The DMX512 protocol was first developed by the USITT as a standard digital interface from the console to the control dimmer. DMX512 surpasses analog systems, but cannot completely replace them. DMX512's simplicity, reliability (assuming it can be installed and used correctly), and flexibility make it the protocol of choice if funds allow. In practical application, DMX512 control mode, is generally the power supply and controller design together. DMX512 controller controls 8 ~ 24 lines, and directly drives the RBG line of LED lamps. However, in the building lighting project, due to the weak DC line, it is required to install a controller at about 12 meters, and the control bus is in parallel mode. Therefore, the controller line is very much, and many occasions can not even be constructed. The receiver of the DMX512 needs to be addressed so that it can explicitly receive dimming instructions, which is also very inconvenient in practical applications. Multiple controllers interconnect to control complex lighting schemes, and operating software design can be complex. Therefore, DMX512 is more suitable for lighting together, such as stage lighting. To sum up, the main disadvantage of DMX controller is that it requires special wiring layout and type, and requires certain programming in order to set the basic color and scene, which is costly for later maintenance.

|